Business Areas

Hanwha Momentum is engaged in secondary battery, display, clean logistics, factory automation, and new and renewable energy industries based on thermal and automation technologies.

We are leaping forward to become a leader in the mechatronics industry along with the growth of our customers by expanding our portfolio, focusing on high-value-added businesses,

expanding overseas markets, developing cutting-edge equipment, and strengthening our production and SW capabilities.

Display

In the case of displays, we have been consistently producing and supplying production equipment through

our endless research and development that covers the CRT, PDP, LCD, and OLED. Especially,

the IR Clean Oven holds the greatest market share globally with its highly differentiated technology.

-

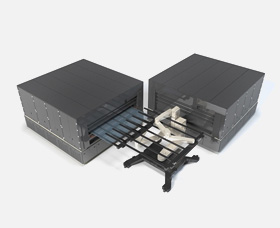

IR CLEAN OVEN for LCDIt is an oven for heating, drying, and the burning of the LCD plate with the IR heater, and its main purpose during the LCD manufacturing process is burning and drying after cleaning at the end of printing the photoresist, polyimide, etc. From the small to 8G glass, it has obtained various kinds of experiences and records so that it is supplied to every kind of customer both domestically and internationally. Due to the use of the IR heater and air distribution system with excellent performances, it is possible to realize high precision temperature control and outstanding outgassing, and other strengths of this equipment include a high purity level (class 10), maintainability, small installation place, low operating cost, etc..

IR CLEAN OVEN for LCDIt is an oven for heating, drying, and the burning of the LCD plate with the IR heater, and its main purpose during the LCD manufacturing process is burning and drying after cleaning at the end of printing the photoresist, polyimide, etc. From the small to 8G glass, it has obtained various kinds of experiences and records so that it is supplied to every kind of customer both domestically and internationally. Due to the use of the IR heater and air distribution system with excellent performances, it is possible to realize high precision temperature control and outstanding outgassing, and other strengths of this equipment include a high purity level (class 10), maintainability, small installation place, low operating cost, etc.. -

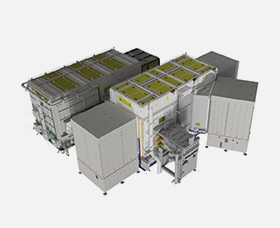

IR CLEAN OVEN for OLEDIt is an oven for heating, drying, and burning of the OLED plate with the IR heater, and its main purpose during the OLED manufacturing process is burning and drying after cleaning. This equipment holds the greatest market share in the world as it is the most suitable for the OLED burning process. Due to the use of the IR heater and air distribution system with excellent performances, it is possible to realize high precision temperature control and outstanding outgassing, and other strengths of this equipment include the high purity level (class 10), maintainability, small installation place, low operating cost, etc. In addition, the latest process technology trend, O2 concentration control, can be implemented.

IR CLEAN OVEN for OLEDIt is an oven for heating, drying, and burning of the OLED plate with the IR heater, and its main purpose during the OLED manufacturing process is burning and drying after cleaning. This equipment holds the greatest market share in the world as it is the most suitable for the OLED burning process. Due to the use of the IR heater and air distribution system with excellent performances, it is possible to realize high precision temperature control and outstanding outgassing, and other strengths of this equipment include the high purity level (class 10), maintainability, small installation place, low operating cost, etc. In addition, the latest process technology trend, O2 concentration control, can be implemented.