Business Areas

Hanwha Momentum is engaged in secondary battery, display, clean logistics, factory automation, and new and renewable energy industries based on thermal and automation technologies.

We are leaping forward to become a leader in the mechatronics industry along with the growth of our customers by expanding our portfolio, focusing on high-value-added businesses,

expanding overseas markets, developing cutting-edge equipment, and strengthening our production and SW capabilities.

Factory Automation

Hanwha Momentum has developed to become the total solution provider that supplies

the optimized logistics system in various kinds of industrial fields.

Based on the smart technology that leads the fourth industrial revolution,

we take the lead in the innovation of logistics which covers all areas including consulting,

designing, installation, and follow-up management.

-

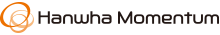

Counter-Balance Forklift Type AGV

Counter-Balance Forklift Type AGVH/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY / LIFT- Max. 1300kg / 1.4~3.0m Lift

- 1.0m/s

BATTERY- Li-Ion / LiFePO4 / Lead Acid Battery

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

- Automatic Battery Exchanger

Introductory video Play clip 1 Play clip 2 -

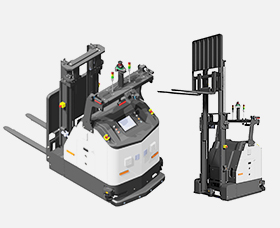

Pallet Truck Type AGV

Pallet Truck Type AGVH/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY / LIFT- Max. 1500kg / 105~240mm Lift

- 1.0m/s

BATTERY- Li-Ion / LiFePO4 / Lead Acid Battery

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

- Automatic Battery Exchanger

Introductory video Play clip 1 Play clip 2 -

High-mast Reach Forklift Type AGV

High-mast Reach Forklift Type AGVH/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY / LIFT- Max. 1000kg / 6.8m Lift

- 1.0m/s

BATTERY- Li-Ion / LiFePO4 / Lead Acid Battery

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

- Automatic Battery Exchanger

Introductory video Play clip 1 -

Conveyor Type AGV

Conveyor Type AGVH/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY- Max. 1100kg

- 1.0m/s

BATTERY- Li-Ion / LiFePO4

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

Introductory video Play clip 1 Play clip 2 -

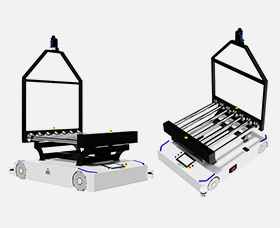

AGV for Secondary Battery (Reel)

AGV for Secondary Battery (Reel)H/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY / LIFT- Max. 250x2kg / 630~1670mm Lift

- 1.0m/s

BATTERY- LiFePO4 / Li-Ion

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

Introductory video Play clip 1 -

AGV for Secondary Battery (Roll)

AGV for Secondary Battery (Roll)H/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY / LIFT- Max. 1500kg / 1200~1480mm Lift

- 1.0m/s

BATTERY- LiFePO4 / Li-Ion

S/W PERFORMANCE

NAVIGATION TYPE- Laser-Reflect Guide

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

-

Light Logistics & Transfer AMR

Light Logistics & Transfer AMR

(Autonomous Mobile Robot)H/W PERFORMANCE

STOP RESOLUTION- ±10mm

LOAD CAPACITY- Max. 3~12kg

- 1.0m/s

BATTERY- LiFePO4 / Li-Ion

S/W PERFORMANCE

NAVIGATION TYPE- SLAM

COMMUNICATION- Wireless LAN Control

- PC-Base

BATTERY CHARGER- Opportunity Fast-Charging

-

AS/RS System (1ton Pallet)It is a standard type stacker crane that is suitable for medium-high buildings with 20~50mH tall equipment and product that weigh 300kg~2ton.

AS/RS System (1ton Pallet)It is a standard type stacker crane that is suitable for medium-high buildings with 20~50mH tall equipment and product that weigh 300kg~2ton.

This rapid and precisely controlled key system for auto-warehouses loads and transfers the cargo onto the racks with its traveling, hoisting, and forking motions.Introductory video Play clip 1 Play clip 2 -

Rack Building SystemIt is a standard type system that is suitable for medium-high buildings with equipment at a height of 20~40mH and product that weigh 300kg~2ton. The rack can be directly installed on the outer wall of a building, which allows a reduction in both the price and space.

Rack Building SystemIt is a standard type system that is suitable for medium-high buildings with equipment at a height of 20~40mH and product that weigh 300kg~2ton. The rack can be directly installed on the outer wall of a building, which allows a reduction in both the price and space. -

KIVA Type AGVThis mobile robot order processing system for real-time picking and the warehousing order processing of small quantity multi-variety products has been developed from the global online platform group and applied to the actual field. It is a future-oriented product that has been widely applied to a wide range of manufacturing and logistics companies.

KIVA Type AGVThis mobile robot order processing system for real-time picking and the warehousing order processing of small quantity multi-variety products has been developed from the global online platform group and applied to the actual field. It is a future-oriented product that has been widely applied to a wide range of manufacturing and logistics companies. -

AGV(Automated Guided Vehicle)Based on diverse platforms and self-developed control technologies for the automation of the manufacturing process, we have commercialized the AGV (Automated Guided Vehicle), where the mobile robot is comprised of the driving part and the collaborative robot that are optimized to handling small goods.

AGV(Automated Guided Vehicle)Based on diverse platforms and self-developed control technologies for the automation of the manufacturing process, we have commercialized the AGV (Automated Guided Vehicle), where the mobile robot is comprised of the driving part and the collaborative robot that are optimized to handling small goods. -

QPS(Quick Picking System)This groundbreaking product for the automated logistics field automatically loads and transfers the cargo by driving to the designated destination with its automated guided vehicle driving system. The AGV is comprised of various kinds of products including the LGV, high-mast LGV, collaborative robot, etc.Introductory video Play clip 1

QPS(Quick Picking System)This groundbreaking product for the automated logistics field automatically loads and transfers the cargo by driving to the designated destination with its automated guided vehicle driving system. The AGV is comprised of various kinds of products including the LGV, high-mast LGV, collaborative robot, etc.Introductory video Play clip 1 -

MSPS(Multi Shuttle Picking System)This system has improved the picking productivity due to the enhanced rate of automation compared to that of the existing DPS. This picking system also provides the continued supply of products to the workers through a connection with real-time orders.

MSPS(Multi Shuttle Picking System)This system has improved the picking productivity due to the enhanced rate of automation compared to that of the existing DPS. This picking system also provides the continued supply of products to the workers through a connection with real-time orders. -

WCS/WMSThis system thoroughly maximizes the entire picking process compared to the Stacker Crane, and it is advantageous that it can freely increase the number of shuttles depending on the volume.Introductory video Play clip 1

WCS/WMSThis system thoroughly maximizes the entire picking process compared to the Stacker Crane, and it is advantageous that it can freely increase the number of shuttles depending on the volume.Introductory video Play clip 1

-

1 Material processRaw materials such as natural and synthetic rubber are automatically loaded and stored through room temperature/high temperature AS/RS.

1 Material processRaw materials such as natural and synthetic rubber are automatically loaded and stored through room temperature/high temperature AS/RS. -

2 Batch processIn this process, the automation system automatically sorts and stores batches produced via batch-off. A stacker crane, RGV, and LGV are used in this process.

2 Batch processIn this process, the automation system automatically sorts and stores batches produced via batch-off. A stacker crane, RGV, and LGV are used in this process. -

3 Rolling processThis process passes steel or fabric cords to the cutting line to cladding rubber on cords; the process consists of AS/RS, Loader, and LGV.

3 Rolling processThis process passes steel or fabric cords to the cutting line to cladding rubber on cords; the process consists of AS/RS, Loader, and LGV. -

4 Process of semi-finished productsThis process produces semi-finished products via the transfer, storage and supply of the materials extruded and rolled in the previous processes. Such products are forwarded to the next processes according to their properties, weight, and shape.

4 Process of semi-finished productsThis process produces semi-finished products via the transfer, storage and supply of the materials extruded and rolled in the previous processes. Such products are forwarded to the next processes according to their properties, weight, and shape. -

5 Molding processThe logistics automation line in this process supplies semi-finished products to the TBM (Tire Building Machine) via the LGV and transports green tires from the TBM to the green tire AS/RS via conveyor or EMS. The EMS guarantees fast and stable system operation thanks to its optimized system design.

5 Molding processThe logistics automation line in this process supplies semi-finished products to the TBM (Tire Building Machine) via the LGV and transports green tires from the TBM to the green tire AS/RS via conveyor or EMS. The EMS guarantees fast and stable system operation thanks to its optimized system design. -

6 GT AS/RSThis system transfers molded green tires to the AS/RS via a tote or conveyor and loads and unloads tires in and from the AS/RS.

6 GT AS/RSThis system transfers molded green tires to the AS/RS via a tote or conveyor and loads and unloads tires in and from the AS/RS. -

7 Curing processThe logistics automation system supplies hardened green tires to the curing machine through the EMS system and feeding conveyor.

7 Curing processThe logistics automation system supplies hardened green tires to the curing machine through the EMS system and feeding conveyor. -

8 Inspection processIn this process, newly vulcanized products are supplied to the visual inspection/trimming/UF/DB systems, and are then stored, loaded and sorted before being transferred to the finished product AS/RS. Conveyors and gantry robots are used.

8 Inspection processIn this process, newly vulcanized products are supplied to the visual inspection/trimming/UF/DB systems, and are then stored, loaded and sorted before being transferred to the finished product AS/RS. Conveyors and gantry robots are used. -

9 Finished product processTires that have passed the inspection line process are sorted by the gantry system according to their product specifications, and are then loaded and unloaded in and from the 50meter high AS/RS and forwarded to the shipping trucks via the release gantry and telescopic conveyor.

9 Finished product processTires that have passed the inspection line process are sorted by the gantry system according to their product specifications, and are then loaded and unloaded in and from the 50meter high AS/RS and forwarded to the shipping trucks via the release gantry and telescopic conveyor.

-

Cross Belt Sorter SystemThe Cross Belt Sorter, a key logistic solution that has maximized the throughput, is a high-speed sorter system that generates low noise and is semi-permanent due to the non-contact LSM (power source) and NCP (power supply).

Cross Belt Sorter SystemThe Cross Belt Sorter, a key logistic solution that has maximized the throughput, is a high-speed sorter system that generates low noise and is semi-permanent due to the non-contact LSM (power source) and NCP (power supply). -

Wheel Sorter SystemThe Wheel Sorter which is an automatic sorting machine is applied with the non-contact type magnet gear so that it is semi-permanent, and is comprised of module units with easy maintenance.Introductory video Play clip 1 Play clip 2

Wheel Sorter SystemThe Wheel Sorter which is an automatic sorting machine is applied with the non-contact type magnet gear so that it is semi-permanent, and is comprised of module units with easy maintenance.Introductory video Play clip 1 Play clip 2 -

QPS(Quick Picking System)This system has improved the picking productivity with a better rate of automation compared to that of the existing DPS. This picking system allows the continued supply of products to the workers through a connection with real-time orders.Introductory video Play clip 1

QPS(Quick Picking System)This system has improved the picking productivity with a better rate of automation compared to that of the existing DPS. This picking system allows the continued supply of products to the workers through a connection with real-time orders.Introductory video Play clip 1 -

Mini Load SystemIt is a stacker crane that has minimized the investment cost and is best suitable to be applied to existing buildings and AS/RS less than 20mH. This quick and precisely controlled key system for auto-warehouses loads and transfers the product on the racks through its traveling, hoisting, and forking motions.

Mini Load SystemIt is a stacker crane that has minimized the investment cost and is best suitable to be applied to existing buildings and AS/RS less than 20mH. This quick and precisely controlled key system for auto-warehouses loads and transfers the product on the racks through its traveling, hoisting, and forking motions. -

AGV(Automated Guided Vehicle)This groundbreaking product in the automated logistics field automatically loads the cargo and transfers it automatically by driving to the designated destination with its automated guided vehicle driving system. There are various kinds of products of AGV including LGV, high-mast LGV, collaborative robot, etc.

AGV(Automated Guided Vehicle)This groundbreaking product in the automated logistics field automatically loads the cargo and transfers it automatically by driving to the designated destination with its automated guided vehicle driving system. There are various kinds of products of AGV including LGV, high-mast LGV, collaborative robot, etc. -

Automated Load SystemIt is a system that can automatically unload various types of cargo. Using the Hanwha Momentum's robot and singular technologies help improve productivity and reduce long-term costs.

Automated Load SystemIt is a system that can automatically unload various types of cargo. Using the Hanwha Momentum's robot and singular technologies help improve productivity and reduce long-term costs. -

WCS/WMSWCS system of Hanwha detects the status of equipment in real-time and maintains the best equipment status through predictive and preventive maintenance functions that identify the power and abrasion conditions. Also, it carries out the real-time data analysis of the whole flow of goods among facilities to provide a general report.Introductory video Play clip 1

WCS/WMSWCS system of Hanwha detects the status of equipment in real-time and maintains the best equipment status through predictive and preventive maintenance functions that identify the power and abrasion conditions. Also, it carries out the real-time data analysis of the whole flow of goods among facilities to provide a general report.Introductory video Play clip 1